Lapho amakhasimende esebenzisa isikhungo semishini esime mpo se-CNC ukuze abone ukucutshungulwa, ngokuvamile ahlangabezana nokunemba kwesitimela okungazinzile noma ezinye izimo.Ngalesi sikhathi, badinga ukulungisa ujantshi ngesikhathi.Phakathi nayo yonke inqubo yokulinganisa, naka izinkinga ezintathu ukuze ugweme ngempumelelo ukwenzeka kukajantshi.s umonakalo.

I-1) Cabangela amandla omshini wesendlalelo sokulungisa ngokwayo kanye nendawo yokusebenza yangempela yesitimela somhlahlandlela.Ngokuphathelene nomehluko phakathi kwezindinganiso ezamukelwayo, ukusebenza, kanye nendawo yokusebenza, lapho kulungiswa, ukulungiswa kwe-welding kanye nokulungiswa kokunamathela kufanele kwenziwe ngokuvumelana nesimo sangempela, futhi izindlela zokulungisa ezithuthukisiwe nezindlela zenqubo kufanele zisetshenziswe.

2) Cabangela ukuthi ingabe inqubo yokukhetha inomthelela ekunembeni nasezimpahleni zemishini zesitimela esiqondisayo.Uma ithintwa izinga lokushisa, noma izobangela ukuthi ujantshi oqondisayo uwohloke, noma uzoshintsha amandla emishini kanye nokuqina kobuso bukajantshi oqondisayo.

3) Cabangela inqubo yokulinganisa ekhethiwe kanye nokufaneleka kwempahla yesitimela esiqondisayo.

I-perpendicularity kanye nokufana phakathi kwama-rails angumhlahlandlela kanye nokuqondisa kwesitimela esiqondisayo endizeni kuzothinta ukunemba kwejiyomethri kwesikhungo semishini eqondile ye-CNC.Ukunemba kwesitimela somhlahlandlela nakho kuyinkimbinkimbi kakhulu.Izakhiwo ezibonakalayo, ukwakheka, nezinto zobuciko kuzonquma ukunemba kwesitimela somhlahlandlela..

Umthelela wokunemba okuvundlile esikhungweni semishini esime mpo se-CNC ungafingqwa kulawa maphuzu amathathu alandelayo:

1. Uma izinga lingafinyeleli ebangeni elishiwo, isikhungo somshini esime mpo se-CNC sizobangela ukuwohloka kwesitimela somhlahlandlela phakathi nomsebenzi wesikhathi eside, futhi ukuma kwezimbazo X kanye no-Y nakho kuzothinteka.

2. Ngemva kokuba umzila wesitimela ukhubazekile, ithebula lokusebenza nalo lizokhubazeka.Kulesi simo, ukuma kwe-spindle kanye netafula lokusebenza nakho kuzoba kubi kakhulu, futhi umphumela uzothinta ukunemba kwemishini yendiza yesikhungo semishini eqondile ye-CNC.

3. Impilo yonke yesevisi yesikulufu somhlahlandlela kanye nesikhungo sokukhanda esima mpo se-CNC sizoncishiswa.

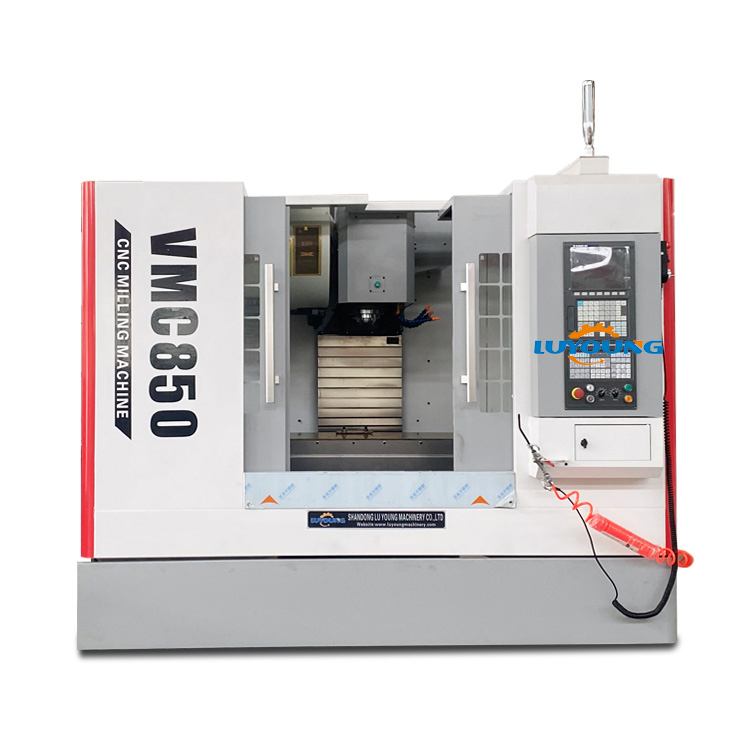

Siyakwamukela ukuze uthintane nezikhungo zethu zemishini eziqondile ze-CNC: vmc420, vmc7126, vmc550, vmc650, vmc850, vmc1060, njll. Sineminyaka engu-20 yesipiliyoni sokukhiqiza futhi sihlinzeka ngemikhiqizo esezingeni eliphezulu namasevisi asezingeni eliphezulu.

Isikhathi sokuthumela: Dec-10-2021