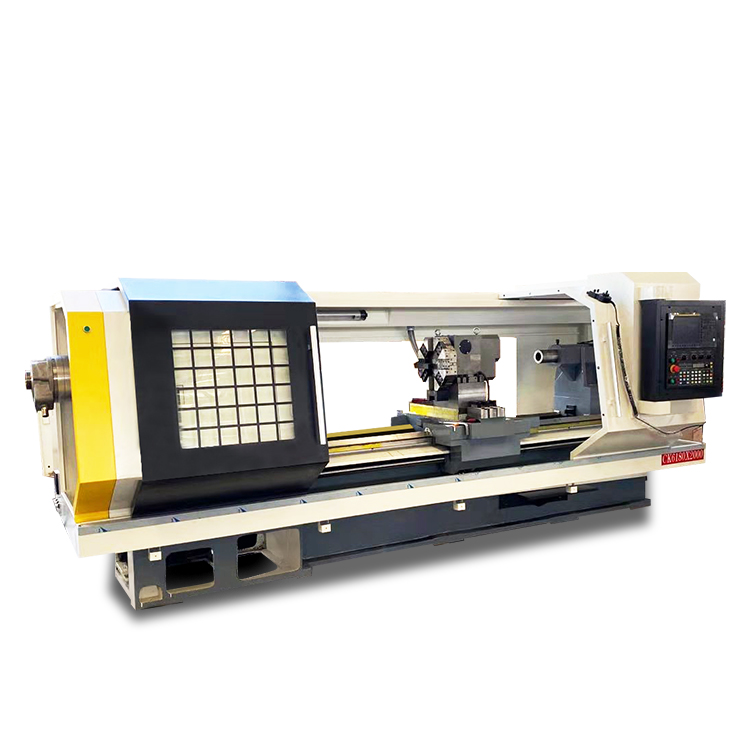

Uhlelo lwe-CNC lwe-lathe lwakhiwe iyunithi ye-CNC, iyunithi ye-servo drive yokunyathela kanye ne-deceleration stepper motor.Iyunithi ye-CNC isebenzisa i-MGS--51 ye-single-chip microcomputer.Uhlelo lokulawula lweyunithi ye-CNC luwumgogodla wokufeza imisebenzi ehlukahlukene.Ubude obuthile bokucubungula, isiqondiso esinyakazayo nesivinini sokuphakela kuyanqunywa.Ngokusekelwa kweyunithi yokucubungula ephakathi, uhlelo lokulawula, ngokusho kwedatha yohlelo lokucubungula okokufaka, lubalwa futhi lucutshungulwe ukuze kuthunyelwe isignali ye-pulse edingekayo, ekhuliswa umshayeli bese iqhutshwa.I-Stepper motor, umthwalo wemishini ushayelwa yi-stepper motor ukubona ukulawula okuzenzakalelayo kwethuluzi lomshini.

1. Vula i-LCD interface ehlela ukuhlangabezana nezidingo zokwenza ngokwezifiso zabakhiqizi bemishini

2. Isibonisi se-LCD enencazelo ephezulu, isistimu ye-lathe inomsebenzi wokulinganisa ithuluzi lengxoxo, futhi isixhumi esibonakalayo sinobungane kakhulu

3. Ukulungiswa kungasethwa kube amadijithi angu-7, isakhiwo sokulawula iluphu evaliwe ngokuphelele, ukunemba okuphezulu kokulawula

4. Umsebenzi wokunxeshezelwa kwethuluzi elicebile

5. Ngesinxephezelo sokubuyela emuva komshini kanye nemisebenzi yesinxephezelo sephutha le-screw pitch

6. Uhlelo oluhlukile lomsebenzi wokuhlola isondo lesandla, umshini wokulwa nokushayisana, ukusebenza okuphephile

7. Ngokulingisa uhlelo, isigaba esisodwa, isigaba sokweqa kanye nomsebenzi wokuqalisa kabusha uhlelo, umsebenzi unamandla kakhulu

8. Ngaphezu kokusekela ikhodi evamile ye-G, ikhodi ye-T kanye ne-S code programming yama-lathes, futhi inikeza izinhlobonhlobo zemijikelezo yokusika engaguquki, imijikelezo ehlanganisiwe kanye ne-MACRO macro programming.

9. Umthamo wokugcina uhlelo ungamabhayithi angu-512 K, futhi iqembu lohlelo lwe-NC lingafika kumaqembu ayi-1000

10. Nikeza isixhumi esibonakalayo esijwayelekile se-RS232C, esingaxhunywa kukhompyutha yomuntu siqu (i-PC) ukuze ubone kalula ukudluliswa kohlelo.

isimiso sokusebenza

Uhlelo lokulawula izinombolo lwethuluzi lomshini lwakhiwe iyunithi yokulawula izinombolo, iyunithi ye-stepper drive kanye ne-deceleration stepper motor.Iyunithi yokulawula izinombolo isebenzisa i-MGS--51 ye-single-chip microcomputer.Uhlelo lokulawula lweyunithi yokulawula izinombolo luwumgogodla wokufeza imisebenzi ehlukahlukene.Ohlelweni lokucubungula izingxenye, Ngokunikezwa ubude obuthile bokucubungula, isiqondiso esihambayo, nesivinini sokuphakelayo, uhlelo lokulawula, ngokusekelwa kweyunithi yokucubungula emaphakathi, ngokuya ngedatha yohlelo lokucubungula okokufaka, ngokubala nokucubungula, ithumela i-pulse edingekayo. isignali, futhi ngemva kokukhulisa amandla omshayeli, I-stepper motor iyashayelwa, futhi umthwalo wemishini udonswa yi-stepper motor ukubona ukulawula okuzenzakalelayo kwethuluzi lomshini.Lapho kwenziwa imicu, i-spindle pulse generator kufanele imiswe ukuze idlulisele isiginali yoshintsho lwe-angular yokuphotha kukhompuyutha.Ikhompiyutha yenza ukuhumusha ngokuya ngephimbo yentambo esethiwe futhi ilawula umbambi wamathuluzi ukucubungula imicu ehlukahlukene.Uhlelo lungathumela noma lwamukele amasiginali we-STM ngokuya ngezidingo zomsebenzisi ukuze kusebenze imishini.

Izinyathelo zokuzivikela

Ukulungisa iphutha lamandla

Faka ugesi namapulagi enjini ngokomdwebo wezintambo, beka iswishi yesikhulisi samandla endaweni yokucisha, bese uvula iswishi yamandla esistimu.Ngemva kokuba amandla evuliwe, iyunithi yokulawula izinombolo kufanele isebenze ngokujwayelekile.Ngalesi sikhathi, ukusebenza kwe-axial flow fan kufanele kuhlolwe, futhi kwenqatshelwe ngokuphelele ukusebenza lapho fan imisiwe.Beka iswishi yesikhulisi samandla endaweni YOKUVULIWE.Hlola mathupha ukuthi idrayivu isebenza kahle yini.Ngokwezinyathelo zokufaka zohlelo, zama ukufaka uhlelo lokucubungula ingxenye, hlola umsebenzi ngamunye, bese lungalungiswa ku-inthanethi kuphela ngemva kokuba seluvamile.Izinyathelo zokuqapha ezisetshenziswayo Uma kutholakala ukuthi isiqondiso sokuzungeza se-motor siphambene nesiqondiso esimisiwe ngesikhathi sokulungisa iphutha, isiqondiso singashintshwa ngokusebenzisa inkinobho yokuqondisa.Isistimu inezidingo eziphezulu kumapharamitha wedivayisi yamandla, ngakho-ke ayivunyelwe ukuyishintsha ngamanye amamodeli ngokuthanda kwakho.Akuvunyelwe ngokuphelele ukufaka noma ukukhipha i-chip ngenkathi amandla avuliwe, noma ukuthinta chip ngezandla zakho.Uma ukushisela kufanele kwenziwe ngesikhathi sokulungiswa, yonke imithombo yamandla yesistimu kufanele inqanyulwe kuqala, futhi zonke izixhumi ezixhunywe kwikhompyutha nangaphandle kufanele zihlukaniswe.Ngaphezu kwalokho, uma i-welding kukhompyutha, ukushisa okusele kwe-soldering iron kufanele kusetshenziselwe ukuvimbela ukulimala kudivayisi yekhompyutha.Ngemuva kokuthi isistimu ivuliwe, uma ingasebenzi isikhathi eside, inkinobho ye-amplifier yamandla kufanele ibekwe endaweni evaliwe ukuze kugwenywe ukukhiya isigaba isikhathi eside, ukuze kuncishiswe ukulahleka kwamadivayisi kagesi nokulahlekelwa amandla. .Ngemuva kokuthi amandla esistimu enqanyuliwe, kufanele ilinde imizuzwana engaphezu kwengu-30 ngaphambi kokuyivula futhi.Akuvunyelwe ukuvula nokuvala amandla ngokuqhubekayo, ngaphandle kwalokho isimo samanje sokusebenza sekhompiyutha sizoba esingavamile, esizothinta ukusetshenziswa futhi singalimaza izingxenye.Qiniseka ukuthi usebenzisa uhlelo endaweni ehlanzekile uma kuqhathaniswa.Uma indawo yesayithi inokhahlo uma kuqhathaniswa (inqwaba yezinhlamvu zensimbi nothuli), umsebenzisi angakwazi ukwengeza izipontshi zokuhlunga endaweni yokungena komoya kanye nokuphuma kwesistimu ngokufanelekile.Iyunithi yokulawula izinombolo yebhethri eyisipele inikwa amandla ibhethri eliyisipele ukuze linikeze amandla ku-RAM chip yengxenye yokucubungula inkumbulo yohlelo kukhompuyutha ngemva kokucisha amandla, ukuze kongiwe uhlelo lokucubungula lwezingxenye zomsebenzisi.Ukushintsha ibhethri kufanele kwenziwe ngekhompyutha ukuze kugwenywe ukulahlekelwa ingxenye yezinhlelo.Lapho ushintsha ibhethri, naka i-polarity ethi "+" kanye "-", futhi ungahlehli uxhumano.Ngemva kokuxhuma, sebenzisa i-multimeter enokumelana okuphezulu kwangaphakathi ukuze ulinganise i-voltage yesokhethi yebhethri kukhompyutha.Inani lereferensi ye-voltage evamile: 4.5V~4.8V.

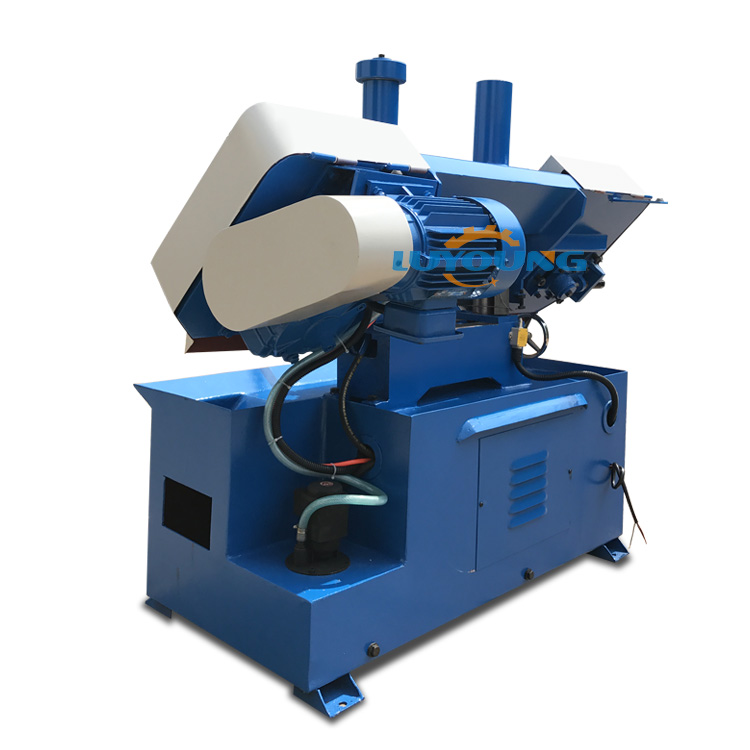

| umshini wokusaha ibhande lensimbi | ||

| Into | I-angeli ye-rotary ye-GT4240 band sawing umshini | I-angeli ye-rotary ye-GT4240 (gantry) band sawing umshini |

| Max.sawing size(mm) | 0 °400, 45° 310, 60° 210 | |

| usayizi we-saw blade(mm) | 1960X34X1.1 | 5160X34X1.1 |

| Isivinini se-saw blade(m/min) | 27X45X69 | |

| I-Saw wheel diameter(mm) | 520 | |

| isivinini sokuphakelayo | engenasinyathelo | |

| Amandla emoto amakhulu(kw) | 4KW | |

| Iphampu ye-Hydraulic motor motor (kw) | 0.75KW | |

| Injini yephampu yamanzi(kw) | 0.04KW | 0.09KW |

| ukusebenza clamping | I-hydraulic clamping | |

| Imodi yeDrayivu | Isibungu kanye negiya | |

| Ubukhulu bebonke(mm) | 2300X1400X1800 | 2300X1400X1800 |

| Isisindo(KG) | 1100KG | 1300KG |

Ibhande lesaha liqiniswe kumasondo amabili esaha, kanti isondo lesaha lishayela ibhande lesaha ukuze lisike.Kunezinhlobo ezimbili eziyinhloko zemishini yokusaha yebhande: mpo kanye nevundlile.Uhlaka lwamasaha lomshini wokusaha webhendi eqondile lusethwa lubheke phezulu, futhi ucezu lomsebenzi luyanyakaza ngesikhathi sokusika ukuze usike ijika le-curve leshidi kanye nengxenye ebunjiwe.Ibhande lesaha lingashintshwa futhi ngeketango lefayela noma ibhande le-sanding ukuze lifake noma lifake isihlabathi.Uhlaka lwamasaha lomshini wesaha ovundlile luhlelwa ngokuvundlile noma ngokutshekile, futhi luphakela ngendlela eqonde mpo noma isiqondiso sokushwiba endaweni ethile.Ibhande lesaha livamise ukusonteka ngo-40° ukuze ligcine amazinyo esaha eqondana nomsebenzi.Uhlobo oluvundlile luhlukaniswe ngohlobo lwesikelo, ikholomu ephindwe kabili, isaha yohlobo lwekholomu eyodwa;ngokusho kokusetshenziswa, ihlukaniswe yaba uhlobo lwemanyuwali (ukudla okunomnotho okwenziwe ngesandla kanye nokusikwa kwezinto ezibonakalayo) kanye nohlobo oluzenzakalelayo;ngokohlelo lwe-automation olusebenzisa isilawuli, lungahlukaniswa lube uhlobo lwemanyuwali (Semi-automatic manual feeding) uhlobo oluzenzakalelayo (ukudla okuzenzakalelayo nokusika okuzenzakalelayo);ngokwezidingo ze-engeli yokusika, ihlukaniswe ngomshini wokusika i-angle (ingabona i-angle yokusika yama-degree angama-90 nama-degree angama-45) ngaphandle kwe-engeli, okungukuthi, ukusika okuqondile okungu-90 degrees.

Izici zomshini wokusaha we-Double Column Horizontal Metal Band Sawing Series Band Sawing Machine:

♣Isakhiwo sekholomu ekabili, ukuphakamisa okuqondile, ukuzinza okuphezulu

♣Ukulawulwa kwe-hydraulic yejubane lokusika, ukulawulwa kwesivinini esingenasinyathelo

♣Ucezu lomsebenzi oluhlanganisa i-hydraulic clamping, kulula ukuyisebenzisa

♣Idivayisi yokuqinisa i-hydraulic yezindlela ezintathu ngokwezifiso

♣Umkhiqizo unezici zesakhiwo esihlangene, ukusebenza okuzinzile, ukusebenza okulula, ukusebenza kahle kokukhiqiza okuphezulu, ukuphepha okuqinile, njll.

♣Ukungeniswa kwe-saw blade, ukuvala shaqa kwesimo esiphuthumayo

Isikhathi sokuthumela: Aug-10-2022