I-C6136 /C6236 umshini omncane wensimbi ovundlile ovundlile

Ukucaciswa

| Imodeli | C6 1/2 36C | ||

| Umthamo wokucubungula | Ubukhulu be-swing diameter phezu kombhede | 360 | |

| I-Max.shwibeka phezu kwesilayidi esiphambanayo | 190 | ||

| Ubukhulu bokuphenduka ububanzi kusihlalo Ubukhulu bokuphenduka ububanzi kusihlalo

| 520 | ||

| Ibanga elimaphakathi | 750,1000,1500 | ||

| Ububanzi bombhede | 360 mm | ||

| I-spindle | Spindle bore | Φ52/80mm | |

| Spindle ekhaleni | C6 | ||

| I-spindle taper | MT6 | ||

| Ibanga lezivinini ze-spindle.Izinyathelo) | 40-1400 (9 izinyathelo) | ||

| Okuphakelayo | Imicu yemethrikhi.Inombolo) | 0.25-14mm (19 izinhlobo) | |

| I-inch threads(Inombolo) | 2-40/intshi | ||

| Intambo ye-modulars(Inombolo) | 0.25-3.5MP (11 izinhlobo) | ||

| Inqola | I-cross slide stroke

I-cross slide stroke

| 180mm | |

| Ithuluzi lokuphumula unhlangothi Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

Ithuluzi elincane lokuphumula unhlangothi

| 95 mm | ||

| ubukhulu besigaba

| 20 x 20mm² | ||

| I-Tailstock | I-taper yomkhono we-tailstock | MT4 | |

| Ububanzi bomkhono we-tailstock | 65 mm | ||

| Ukushaywa komkhono we-tailstock | 140mm | ||

| Injini eyinhloko | 4kw | ||

| Usayizi wephakheji: (L xWxH) |

| ||

| Ibanga elimaphakathi 750 mm | 2220 x 1150 x 1590mm | ||

| 1000mm | 2470 x 1150 x 1590mm | ||

| 1500mm | 2970 x 1150 x 1590mm | ||

| Isisindo:NW/GW.KG) |

| ||

| Ibanga elimaphakathi 750 mm | 1350 | 2000 | |

| 1000mm | 1450 | 2100 | |

| 1500mm | 1600 | 2250 | |

Izici eziyinhloko zomkhiqizo

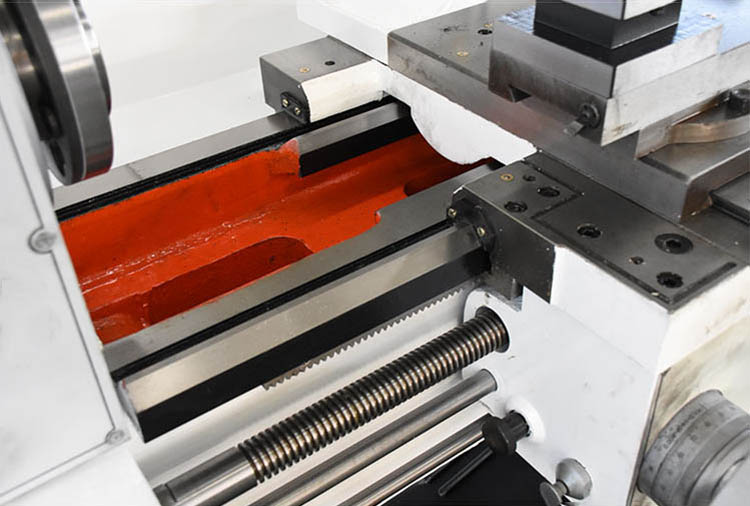

1. Umbhede nemilenze yawo yenziwe ngensimbi enamandla amakhulu ukuze kuqinisekiswe ukunemba okungcono, kuyilapho kunciphisa ukudlidliza nokuqinisekisa ukuzinza kwethuluzi lomshini ukuze lisetshenziswe isikhathi eside: ama-rails omhlahlandlela wombhede ayindawo eqondile ngemva kokucinywa kwe-ultrasonic ukugcina amandla , Ihlala isikhathi eside futhi ayigugi, ukuqinisekisa impilo ende yesevisi yethuluzi lomshini, futhi kunciphise nokugcinwa kwethuluzi lomshini.

2. I-headstock icutshungulwa ngemishini yokunemba ukuqinisekisa ukuthi izingxenye eziyinhloko zethuluzi lomshini zidingeka kancane.Ngesikhathi esifanayo, ama-bearings ebhokisini athengwa emikhiqizo kazwelonke.I-spindle namagiya angaphansi kwezindlela ezikhethekile ezifana nokucisha imvamisa ephezulu kanye nokugaya okunembayo ukuze kuncishiswe umsindo womshini.Kwenza ukusebenza kukonke komshini kube ngcono kakhulu.Izindawo ezihlanganyelwe phakathi kwe-headstock yethuluzi lomshini kanye nepuleti lokusekela le-tailstock lethuluzi lomshini liyakwenwa mathupha futhi ligaywe ngabasebenzi.Wonke umshini uye wahlolwa ngokuqinile ukuze kuqinisekiswe ngempumelelo ukunemba nokuzinza kwethuluzi lomshini.

3. Umshini wokushintsha isivinini oyingqayizivele webhokisi lommese ungadlulisela ngokunembile ukuguqulwa kwesivinini sengxenye yesitoko sekhanda kusikulufu sokuhola.Ukukhethwa kochungechunge lwemethrikhi neyintshi kuphaneli, ithebula lesithenjwa lamapharamitha wobuchwepheshe, nemiklamo ehlukahlukene eyenziwe umuntu iqinisekisa ukuthi opharetha bangasebenza ngokushesha, ngokuphepha nangokushesha.

4. Ibhokisi lamaslayidi, ukuhlaziya kwesayensi nokubala, ukuxhumanisa okuphusile kwamagiya.Ukuzungezisa kwesikulufu somthofu kudluliselwa ngokunembile kuzihlalo zezihlalo ezivundlile neziphakelayo eziqondile ukuze kuqinisekiswe ukugcwaliseka komsebenzi wokucubungula usayizi wethuluzi lomshini.

5. I-tailstock icutshungulwa kusukela ekuphenduleni okunamandla nokuhle, ukucisha, ukugaya okuqinile nokucolile, futhi wonke umshini uhlanganiswe ne-headstock spindle ukuze kulungiswe i-contour ephakathi ukuze kuqinisekiswe ukunemba kwezingxenye ezicutshunguliwe.

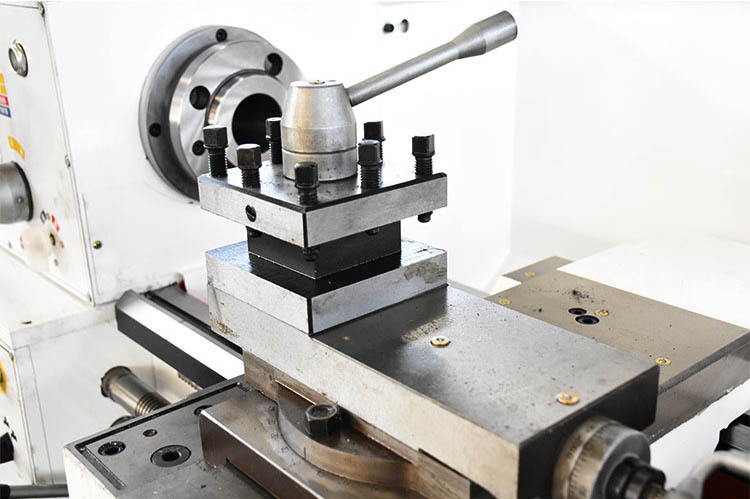

6. Idizayini yesibambi samathuluzi inhle, ukugoqa ithuluzi kulula, futhi isibambi samathuluzi esineziteshi ezine samandla aphezulu siyamukelwa.

7. Lo mshini uthola ukufakwa okuzimele kobuchwepheshe bepompo yamanzi ukuze kuqinisekiswe ukupholisa nokunciphisa izinga lokushisa ngesikhathi sokucubungula ukuthuthukisa ukunemba kwezingxenye.

Imibandela yokusebenzisa umshini

1. Izidingo zemvelo zendawo yethuluzi lomshini: Indawo yethuluzi lomshini kufanele ibe kude nomthombo wokudlidliza, ukukhanya kwelanga okuqondile nemisebe eshisayo, futhi umswakama nokugeleza komoya kufanele kugwenywe.Uma kunomthombo wokudlidliza eduze kwethuluzi lomshini, umsele ovimbela ukudlidliza kufanele usethwe eduze kwethuluzi lomshini.Uma kungenjalo, kuzothinta ngokuqondile ukunemba komshini nokuzinza kwethuluzi lomshini, futhi kubangele ukuthintana okungalungile kwezingxenye ze-elekthronikhi, ukwehluleka, futhi kuthinte ukuthembeka kwethuluzi lomshini.

To

2. Izidingo zamandla: Ngokuvamile, ama-lathes afakwe ku-workshop yemishini, engenakho nje kuphela izinguquko ezinkulu zokushisa kwemvelo kanye nezimo ezimbi zokusetshenziswa, kodwa futhi inemishini eminingi ye-electromechanical, ebangela ukushintshashintsha okukhulu kwegridi yamandla.Ngakho-ke, indawo lapho i-lathe evamile ifakwe khona idinga ukulawulwa okuqinile kwe-voltage yokunikezwa kwamandla.Ukushintshashintsha kwamandla kagesi kufanele kube phakathi kwebanga elivumelekile futhi kuhlale kuzinzile.Uma kungenjalo izothinta ukusebenza okuvamile kohlelo lwe-CNC.

3. Izimo zezinga lokushisa: Izinga lokushisa elizungezile lombhede ovamile lingaphansi kwama-degree Celsius angu-30, futhi izinga lokushisa elihlobene lingaphansi kuka-80%.Ngokuvamile, isiphephetha-moya esikhipha umoya noma isipholile somoya sihlelwa ngaphakathi kwebhokisi lokulawula izinombolo likagesi ukuze kugcinwe izingxenye ze-elekthronikhi, ikakhulukazi izinga lokushisa elimaphakathi leyunithi yokucubungula lingaguquki noma umehluko wezinga lokushisa ushintsha ube mncane kakhulu.Izinga lokushisa elidlulele kanye nomswakama kuzonciphisa impilo yezingxenye zesistimu yokulawula futhi kubangele ukwehluleka okwengeziwe.Ukwanda kwezinga lokushisa nomswakama kanye nokwanda kothuli kuzodala ukunamathela ebhodini lesifunda elihlanganisiwe futhi kubangele izifunda ezimfushane.

4. Sebenzisa ithuluzi lomshini njengoba kucacisiwe kumanuwali: Uma usebenzisa ithuluzi lomshini, umsebenzisi akavunyelwe ukushintsha amapharamitha asethwe umkhiqizi kusistimu yokulawula ngokuthanda kwakhe.Ukulungiselelwa kwalawa mapharamitha kuhlobene ngokuqondile nezici eziguquguqukayo zengxenye ngayinye yethuluzi lomshini.Inani kuphela lepharamitha yesinxephezelo segebe elingalungiswa ngokuya ngesimo sangempela.Umsebenzisi akakwazi ukumiselela izesekeli zethuluzi lomshini ngokuthanda kwakhe, njengokusebenzisa i-hydraulic chuck eyeqa ukucaciswa.Lapho usetha izesekeli, umenzi ucabangela ngokugcwele ukuhambisana kwemingcele ehlukahlukene yesixhumanisi.Ukushintshwa okungaboni kubangela ukungafani kwamapharamitha esixhumanisi ahlukahlukene, futhi kubangele nezingozi ezingalindelekile.Ukucindezela kwe-hydraulic chuck, ukuphumula kwethuluzi le-hydraulic, i-hydraulic tailstock, ne-hydraulic cylinder kufanele kube ngaphakathi kwebanga lokucindezeleka elivumelekile, futhi noma yikuphi ukunyuka akuvunyelwe.