I-Awr22 idayimane yokusika i-alloy wheel rim ukulungisa umshini

Inkampani yethu ithuthukise isilawuli se-PC esisha sokulungisa ubuso besondo abalimele.Umshini usebenzisa i-PC yezimboni engu-17'', ukuze umshini ulahle ukusebenza okuyinkimbinkimbi nezinkinobho eziningi zesilawuli se-CNC ezingenamsebenzi.Futhi zonke izinyathelo zizoqedwa ku-PC.

Ukucaciswa komshini wokukhanda amasondo e-alloy

| I-alloy wheel ukulungisa umshini | AWR22 | AWR25 | AWR28 | AWR32 | |

| Isilawuli se-CNC | Isikrini sokuthinta Operation 17" Isibonisi se-LCD | ||||

| Ubukhulu.shwibeka embhedeni uDiya. | 610 | Φ635 | Φ770 (30') | Φ880(34') | |

| Ubukhulu.Layisha isondo lengxubevange Usayizi | 22 amayintshi | 22 amayintshi | 28 amayintshi | 32 amayintshi | |

| I-stroke elungisekayo yenkampani yenethiwekhi iqonde ku-X | 100mm | 100mm | 100mm | 100mm | |

| Uhambo lwesilayidi esiphambanayo (mm) | 300 | 320 | 390 | 450 | |

| Ububanzi besitimela (mm) | 260 | 300 | 330 | 400 | |

| Ubude besitimela (mm) | 500 | 700 | 750 | 750 | |

| Uhlobo lokugoqa | 10' chuck/self-centering | 12' i-chuck/self-centering wheel clamping | 16' i-chuck/self-centering wheel clamping | ||

| Uhlobo lophenyo | I-Probe noma i-laser | ||||

| Ibanga lejubane lokuphotha (RPM) | 50 ~ 2500 | 50 ~ 2500 | 50 ~ 2000 | 50-1800 | |

| Ukulawula isivinini se-spindle | Okuzenzakalelayo | Okuzenzakalelayo | Okuzenzakalelayo | Okuzenzakalelayo | |

| I-spindle bore (mm) | Φ60 | Φ60 | Φ82 | Φ82 | |

| Ubukhulu.usayizi wokuthunyelwe kwethuluzi | 25×25mm | 25×25mm | 25×25mm | 25×25mm | |

| Iziteshi zenkampani yenethiwekhi yamathuluzi | 4 isikhundla | 4 isikhundla | 4 isikhundla | 4 isikhundla | |

| Okuncane.ukusetha iyunithi yemoto | (Z) ubude 0.001mm | ||||

| (X) isiphambano esingu-0.001mm | |||||

| Isivinini esihambayo sokuthunyelwe | (Z) ubude 8m/min | ||||

| (X) nqamula u-6m/min | |||||

| Amandla emoto | 4KW | 4kw | 5.5KW | 7.5KW | |

| Ubulukhuni bobuso | I-Ra 0.8-1.6 | ||||

| Usayizi womshini | (L×W×H) (mm³) | 1900*1400*1750 | 2100*1500*1750 | 1990×1600×1860 | 2470×1660×2080 |

| Usayizi wephakheji(mm) | 2000*1400*1750 | 2200*1500*1950 | 2150×1750×2100 | 2620×1810×2300 | |

| Isisindo sengqikithi | 1300kg | 1700kg | 2000kg | 2500kg | |

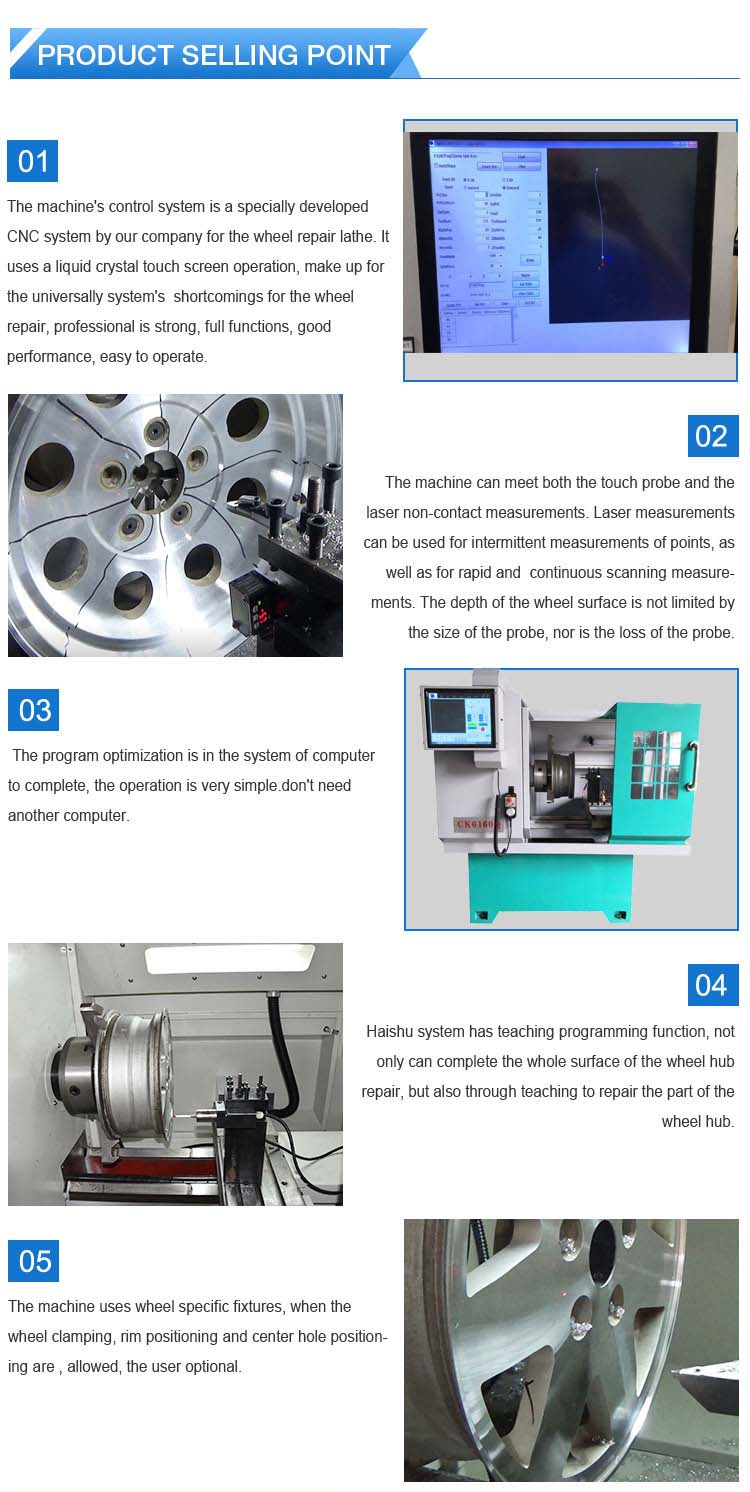

Inzuzo

1. I-lathe yesondo inezinzuzo zesakhiwo esilula, izindleko eziphansi kanye nenani eliphezulu lokusebenza isilinganiso.

2. Ithuluzi lomshini lingakhethwa ngokuskena nge-laser noma ukulinganisa kokuchofoza kwe-probe.

3. Idatha yesondo igcinwa ngokuzenzakalelayo, uhlelo lomshini lubizwa ngokungafanele.

4. Ukuthuthukiswa okuzimele kwesoftware, uhlelo luzilungiselela ngokuzenzakalelayo

5. Ukucubungula amasondo kunembile futhi kuyashesha

6. Ithuluzi lomshini lisebenza isikrini sokuthinta, futhi isixhumi esibonakalayo sesistimu sisekela izilimi eziningi.

7. Isilinganiso se-eksisi ye-X / Z, indawo yesondo kanye nomshini ojikelezayo.

8. Umshini wamasondo ufakwe uhlelo lokuthambisa oluzenzakalelayo.

9. Ilathe enethuluzi ledayimane eliphendukayo, yenza indawo yesondo ibe bushelelezi.

10. I-lathe yokulungisa amasondo inomsebenzi wokufundisa wekhompyutha.

11. Umshini ungenziwa ngokwezifiso ngokuvumelana nezidingo zamakhasimende

Izidingo zokusebenza

1. Uma abantu ababili besebenza, osebenza ngemuva kwesisetshenziswa akumele abheke lapho kuphuma khona umshini wokudweba ngocingo, ukuze avimbele ucezu lokusebenza ukuthi ungandizeli uphumele ngaphandle futhi ulimaze abantu.

2. Kuvinjelwe ngokuqinile ukulungisa ukujula komdwebo wezintambo zehabhu lesondo ngaphansi kwezimo ezijwayelekile zokusebenza, ukuze ugweme imishini kanye nezingozi zomuntu siqu ezibangelwa ukulahlekelwa ukulawula ithuluzi lokuguqula.

3. Faka ihabhu ngendlela efanele.Hlola ngokucophelela ukuthi izihlalo zokuthwala ezingaphezulu neziphansi kanye nesikulufu esiphakamisayo zigcotshwe kahle yini, futhi uqiniseke ukuthi akukho muntu ngaphambili kokukhipha ngaphambi kokuqala umshini.

4. Ukulungiswa kokujula komshini wokudweba kufanele kube okulinganiselwe.Ngaphansi kwezimo ezijwayelekile, inkomba yokujula komdwebo kufanele ibe phakathi kuka-0.2-0.05, futhi kwenqatshelwe ngokuphelele ukweqa u-0.3MM ukugwema okokusebenza noma izingozi zomuntu siqu.

5. Akuvunyelwe ngokuphelele ukubeka ucezu lomsebenzi ngqo ku-fixture, futhi kwenqatshelwe ngokuphelele ukubeka ucezu lomsebenzi bese udweba ucingo ngaphandle kokuvala umnyango wokusebenza futhi ngaphandle komugqa wokuvimba, ukuze ugweme ucezu lomsebenzi ukundiza ngaphandle. nokulimaza abantu.

6. Ngemuva kokuthi umshini wokudweba ucingo lwehabhu uqalisiwe, hlola ngokushesha ukuthi ukushwibeka kwehabhu kungaphakathi kwebanga elidingekayo nokuthi zikhona yini ezinye izinto ezingavamile, ngaphandle kwalokho, kufanele kulungiswe noma kuvalwe ngokushesha.

Lungisa amasondo aqediwe aboniswayo